Using community waste to generate community power.

GSWT Brings you Vision Waste

Reducing emissions. Reducing landfill. Generating community power.

About Us

Our Vision Waste projects power communities with base load renewable energy supply, further reducing the footprint of waste management in Australia. Our goal is to eliminate landfilling in line with government policy, circular economic policy, and GHG emission reduction targets.

Great Southern Waste Technologies (GSWT) is an Australian family owned company with a mission to bring Visionary waste-to-energy (WtE) solutions and resource recovery centres to Australia’s waste management systems.

Inspired by the vision of the late John and Barbara Gilbert, we are committed to bringing innovative and sustainable solutions to the waste management sector.

Our technology delivers better outcomes and reverses the trend of ever-increasing amounts of waste destined for landfill. Through collaboration with all levels of government, we can ensure implementation of sustainable waste policy is effective, efficient and timely.

Great Southern Waste Technology has procured exclusive Australian rights to the state-of the-art WtE technology owned by Norwegian company Energos AS.

It’s all about acting on a VISION for WASTE

GWST’s vision is to achieve zero waste to landfill and significantly reduce the emissions generated by handling and transporting waste. With ENERGOS small scale gasification technology.

We provide a sustainable waste solution using clean, proven, and safe waste infrastructure. We offer the complete suite, taking projects from initiation through development, construction, commissioning, and continuing into lifespan operation and maintenance.

Our Team

Craig Gilbert

Craig has an holistic world view, and along with reducing waste and waste emissions, he supports reducing domestic violence, achieving gender equality in pay rates and positions, valuing and respecting the unique culture and contribution of First Nations people.

Stuart Gilbert

Stuart brings a wealth of knowledge, with skills in fabrication, electrical construction, telecommunications, civil construction, and fitting and turning. His deep understanding of plant and processing systems has proved invaluable.

Stuart joined GSWTin 2018 to help drive projects from concept stage through to completion. He is responsible for general project management, engineering, budgets, timelines and scope.

Stacey Gilbert

Stacey is our newest member and brings a bright and cheerful perspective to our team. Since joining in early 2021, she has already implemented:

• OHS practices and procedures

• BMS policy & procedures systems base

Stacey holds a Certificate III in Civil Construction, a Certificate III in Hospitality & Tourism and a Certificate in Environmental Law & Compliance

Our Partners

Energos AS

A leading supplier of small-scale waste-to-energy plants and technology, Energos AS provides an innovative, local solution for the treatment of municipal, commercial and industrial waste. Energos AS plants convert waste into renewable energy. This energy is used to provide local communities with heat and power.

SOLO Resource Recovery

With over 85 years of experience, SOLO is well equipped to deliver all types of business waste services, making them a preferred partner. SOLO is expert at handling the safe disposal of all business waste materials, including dangerous or hazardous waste. They understand the complexities in planning scheduled waste collections for business, and they prioritise safety. Their waste management solutions are tailored to ensure that waste is removed efficiently with as little disruption to business as possible.

SMEC Holdings

In Australia, SMEC has more than 70 years experience in delivering nation-building projects, providing specialist expertise and technology-driven solutions. Their core service offering covers the lifecycle of a project, from initial concept, feasibility, planning and design through to construction, commissioning, operation and maintenance.

Their network of global specialists allows them to collaborate with local partners, providing the best teams and capabilities to deliver fit for purpose, sustainable solutions.

FAQ

What is Resource Recovery?

By taking waste destined for landfill, GSWT has the capacity to sort and direct materials that can be viably recycled. The residual waste is utilised in the waste-to-energy (WtE) gasification process to generate heat, steam, or electricity.

Why do we need Resource Recovery?

Currently waste from commerce and industry sectors is not sorted and goes directly to landfill, largely due to cost imperatives. GWST is offering a viable solution with economic, environmental and social benefits.

How does Gasification for waste-to-energy work?

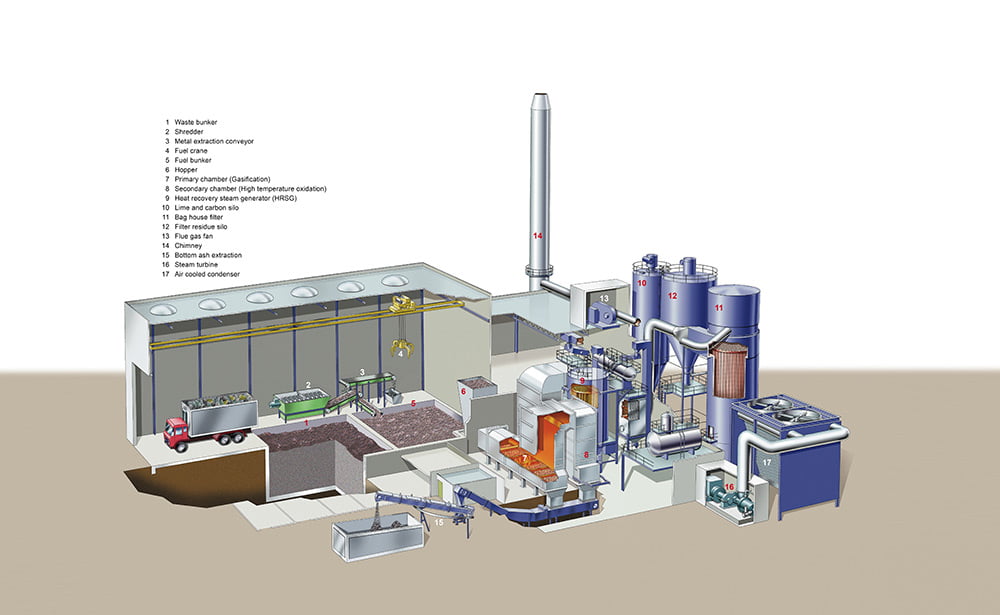

The ENERGOS AS technology uses a 2 stage gasification process which operates at constantly low emission levels, by using a thermal conversion process, which involves:

- Advanced pre-treatment, with further recovery of metals and other commercially valuable materials.

- Gasification technology to facilitate the manufacture of a syngas for use as a fuel in the heat generation process. Waste is introduced into an oxygen starved environment to produce a syngas, then into a secondary chamber where it is combusted to produce heat.

- Hot flue gas entering a high recovery steam generator produces steam at 40 bar for heat, steam or electricity generation with approximately 40 MW energy produced (11MW Power).

- A bottom ash product results, with a range of civil construction applications.

Low impact process treatment and engineered management of emissions falls well within EU emission guidelines.

This process is flexible and can be adjusted for changes in the composition of residual waste or in the type of waste fractions being treated.

While waste-to-energy is an important part of the waste industry in Europe, Australia lacks an established market. GSWT and its partners are working to educate policy makers, communities and the wider waste sector on the benefits of generating energy using waste.

What are the benefits of waste-to-energy technology?

Converting waste to energy is a commercially viable way to provide certainty and improvement in economic, environmental and social outcomes for the treatment of waste streams destined for landfill. It operates at a municipal level and is easily replicable in other locations.

These facilities can reduce the residual waste sent to landfill by at least 80%, and up to 100%, significantly reducing environmental impacts and offering operational and financial benefits.. This supports transition to a true circular economy and 2050 zero carbon targets.

What are the Environmental benefits?

- Low and stable emissions under the EU limits adopted by EPA Victoria .

- Lower emissions from collector vehicles due to reduced transport distances.

- Low visual, odour, and acoustic impact, due to the small building footprint, and the unique process.

- Methane gas emissions from landfills eliminated.

- Reliance on landfill sites reduced, resulting in more productive use of land, and benefiting surrounding areas.

- Supports the Circular Economy in line with all levels of government future waste policy.

- Reduced demand on resources, reduced waste.

- Assists governments in exceeding progress measures in recycling. E.g. would achieve outcomes which exceed these ‘Recycling Victoria’ progress measures:

- 1. Divert 80 per cent of waste from landfill by 2030, and an interim target of 72 per cent by 2025.

- 2. Cut total waste generation by 15 per cent per capita by 2030.

- 3. Halve the volume of organic material going to landfill between 2020 and 2030, with an interim target of 20 per cent reduction by 2025.

- Aligns with the United Nations Sustainable Development Goals, including Goal 8 (‘promote sustained, inclusive and sustainable economic growth’) and Goal 12 (‘ensure sustainable consumption and production patterns’).

What are the Operational benefits?

- The proprietary control system ensures emissions are consistently low and stable, demonstrating world-class efficiencies with many parameters below the 10th percentile of emission limits.

- The minor process treatment required provides low impact emissions, well within the EU emission guidelines.

- The technology is proven, with almost 1,000,000 operating hours of plant reference data.

What are the Financial benefits ?

- Financial modelling demonstrates a very profitable project and sound business case.

- Existing plants are commercially successful, with low operating and maintenance costs.

- The plant produces renewable baseload power, helps achieve Renewable Energy Targets (RETs), and enhances income streams.

- Energy recovered from the biomass content is not subject to the Climate Change Levy (CCL).

- Energy recovered from the biodegradable fraction of waste is exempt from CO2 emissions under the EU Emissions Trading Scheme (ETS).

- Pre tax Internal Rate of Return (IRR) calculated at 14% based on a gate fee of $240.00/ tonne (2024).

Current Projects

Dandenong South Facility

EPA Victoria has granted works approval for the first Vision Waste project by GWST, being deployed in Dandenong South. At this plant, proven Energos AS gasification technology will recover energy and export it to the grid as base load power, available to both commercial and residential customers. This plant will have capacity to process 100,000 tonnes of municipal solid waste, and commercial and industrial waste, delivering approximately 10 megawatts of electricity to the grid each year.

Status:

- Government approvals

- Partner agreements formalised

- Detailed engineering commenced